Strong Point

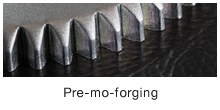

What is Pre-Mo-Forging?

The term comes from a combination of press, modeling, and forging.

It is a fabrication process which fuses pressing (of metal plates) and forging (from metal ingots), and can create product shapes like those made with forging, but using press machines. With existing standard pressing methods, the thicker the plate being pressed, the more rollover occurs. For products where such rollover is unacceptable, additional machining is required.

We believe that this extra processing is wasteful, and so we set about to develop the technology to create pressed products (using existing pressing machines) that had clean-cut surfaces/no fracture surfaces without the need for additional machining.

Compared to machined products, costs are 30 to 40 percent lower.

Usable on a variety of pressed cross-sections

Clean surfaces straight from the pressing machine

Cog teeth made by pressing alone

Can be used to make extremely detailed shapes

Pre-Mo-Forging Merits

- Use existing pressing machines (No need for specialized machines)

- Perfect for mass production

- Large cost savings

- Machining-level precision

- Can produce shapes that normally must be created by forging

Method Comparison

| Method | Mass productivity | Cost | Precision | Equipment |

|---|---|---|---|---|

| Pre-Mo-Forging | ◎ | ◎ | ○ | ◎(Can use existing pressing machines) |

| Fine Blanking | ○ | ○ | ○ | ×(Requires specialized equipment) |

| Forging press and Machining | △ | △ | ◎ | △(Requires forging press and machining tools) |

◎Excellent ○Good △Not good ×Poor

Machining means costs cannot be reduced. If you need precision parts created by pressing, please talk to Hanya Seisakusho’s sales department.

![]()