事業案内

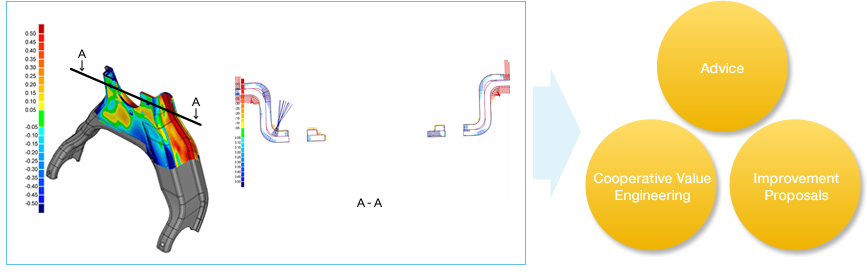

Proposing Products and Working with Our Customers

We don’t just take measurements; we deliver value engineering and improvement suggestions tailored to customer requirements. We build on our test data and work with customers to create better products.

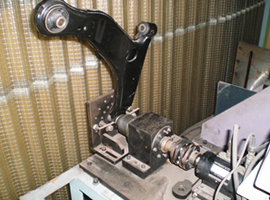

Mounted Durability TestWe use a frame to mount the part and duplicate actual vehicle conditions, and then subject it to repeated loads. We test for effects of stress concentration due to deflection from repeated loads.

Rotating Torque MeasurementTo assess control responsiveness, we measure rotating torque of parts that transmit movement.

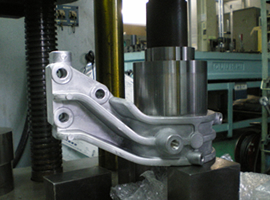

Static Strength TestWe mount the part on a jig and apply static loads. We assess part stiffness by measuring displacement and stress.

3D Measuring Device (Laser)Laser measurements enable us to assess 3D shape by comparing part to CAD data.

Natural Vibration MeasurementWe attach accelerometers to the part to measure vibration transference routes. We use FFT processing to measure natural vibrations.

MicroscopeEnlarged view of the part enables us to perform very detailed measurements. We can also assess surface shape.

![]()