Strengths of HANYA

Integrated Production System, from Development to Assembly

We are a one-stop manufacturer, able to handle everything from development and design to assembly (complicated pressed products, welding, assembly, machining, painting). Our strength is that we handle everything in-house, in our own factories.

For example, supervisors for each stage of the production process can meet at a moment’s notice, enabling everyone to quickly understand production flow and problems.

As well, feedback is smoothly channeled from the production lines back to the designers. This is a key point in our ability to engage in high-level processing of the products we handle.

Our integrated production (integrated quality assurance) also helps us achieve high product quality.

■ Merits of Hanya’s Integrated Production

- ・Communication takes place between departments, not companies, resulting in smooth information flow and stable quality.

- ・Product quality can be immediately assessed between processes, making it easy to optimize quality.

- ・ History of past problems and issues is shared, creating an environment where it is easy to improve quality.

- ・Quality assurance management can be integrated.

R&D and Design Department

We can dispatch guest engineers to your company, and through joint improvement activities, develop expertise, improve quality, and reduce costs.

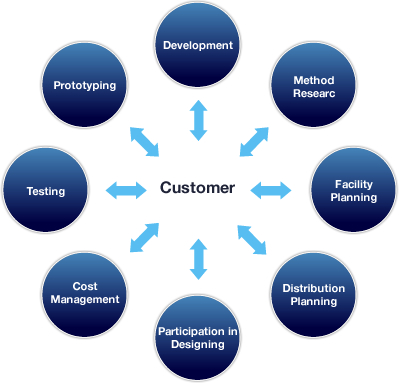

■ Flexible Production Responsive to Customer Needs

We are involved with producing a large range of suspension parts and fittings, parts that cannot properly be understood without imagining how they work in the completed vehicle. There are many important factors that go into these parts beyond the design drawings, and we believe it is our role to be a partner company that can identify these factors quickly and make proposals and provide quality products to our customers.

As well, we work to improve customer satisfaction by holding periodic discussion meetings and conducting information exchange visits (especially to identify problems). Our creative thinking and comprehensive facilities mean we can respond flexibly to customer requirements. This is what makes us Hanya Seisakusho, a company that delivers ideas and proposals.

Production Technology Department

■ Working With Customers to Create New Products, Using the Latest Technology and Expertise

When developing new products, our forward-facing efforts focus on creating products with cutting-edge materials. In recent years, we moved early to introduce high-tensile materials, progressing from CAE analysis to development in only one year. As well, we have the systems within the company for prototyping new products and assuring quality through durability testing.

Processing Technology Department

■ Manufacturing Complicated Parts With the Industry’s Leading Processing Technology

We specialize in the production of parts with complicated or difficult shapes.

Here are some representative examples:

Ultra high-tensile materials: Using 1180 Mpa-class high tensile steel plate for weight reduction with increased strength

Aluminum plate: We work with the automobile industry’s thinnest aluminum plate (0.35 mm)

Heavy plate: We work with the automobile industry’s thickest steel plate, at 12 mm thickness.

And we can do more besides.

![]()